Max Private Label understands that quality is critical to every one of our customers and their end-users. Quality protects your brand and our reputation. Therefore, all of our operations are governed by a comprehensive Quality Manual, administered by our Quality Control Unit.

Why MPL

Research: Max Private Label is based on its R&D capabilities that allows us to not only have a micro understanding of our products, and also stay ahead of the curve in terms of exploring new applications and new ingredients.

Product Evaluation: MPL believes that to develop quality products there needs to be testing not only inside the research and development but, also with the end customers. MPL has created a full product testing center where daily product testing occurs of our brands and customer brands create by us.

Turnkey Capabilities: Our sourcing and procurement team can work with any customer to help develop the best product/program for them. This capability has brought many of our customers to completely outsource their supply chain with MPL, all the way to shipment directly to the point of sale. With Max Private Label turnkey services clients

At Max Private Label (MPL), we maintain a team of trained and experienced professionals who can produce and inspect batches to maintain high quality standards. Our facility maintains strict Standard Operating Procedures (SOPs) so that every run of cosmetic and personal care products is consistent, including:

- Creams

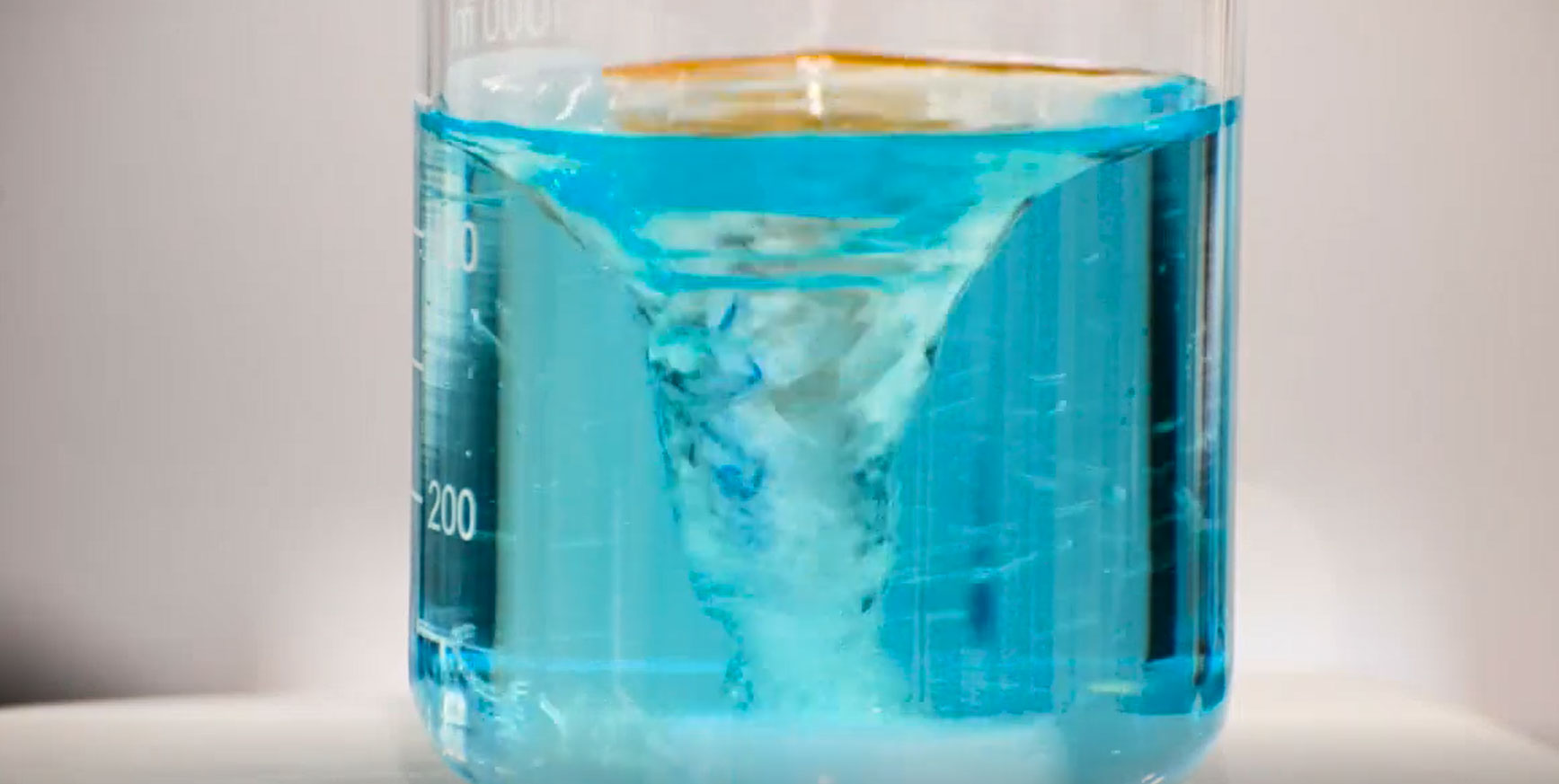

- Emulsions

- Hot fills

- Liquids

- Lotions

- Serums

Our 300,000 square foot facility houses batching tanks and filling lines designed to accommodate a wide range of custom formulas and designs and manufacture them to exact specifications. This top-of-the-line equipment allows us to provide consistent, high quality products in a variety of batch and order sizes.

Your Formulas + Our Current Good Manufacturing Practices (cGMPS)

To achieve the highest quality standards, MPL strictly adheres to current good manufacturing practices (cGMPS) and maintains FDA site registration for cosmetics.

cGMPS are established standards that regulate how manufacturers design, monitor, and control the manufacturing process. Compliance with cGMPS prevent process contaminations, errors, and low-quality product manufacturing. While the regulations establish strict standards regarding raw materials, equipment, and testing processes, they also give manufacturers the flexibility to produce a wide variety of specialty products. At MPL, hiring companies can design or formulate their products to meet their unique needs, and we will ensure that the products are manufactured according to these FDA standards.

Finding and hiring a contract manufacturer that adheres to cGMPS is important for product quality control and consumer safety. Cosmetics and personal care products designed and manufactured under cGMP regulated conditions and practices are inherently assured quality throughout the production process. Additionally, cGMP requires the employment of qualified and fully trained equipment operators, reliable systems, and testing procedures to guarantee the safety and efficacy of the produced products.